We systematically improve our maintenance abilities for railway rolling stock to grow our business.

- We autonomously carry out maintenance and related management work, and work together with JR East to further develop the functions of the JR East General Rolling Stock Center.

- We create a database of rolling stock maintenance and use the condition monitoring inspection method to realize condition-based maintenance (CBM).

- We contribute to the JR East Group by improving the quality and efficiency of maintenance and modification work for JR East’s rolling stock.

- As a company specialized in rolling stock, we develop core technologies for the growth of the railway business.

Maintenance of JR Shinkansen Rolling Stock

The Shinkansen Office is located in the JR East Shinkansen General Rolling Stock Center in Rifu-cho, Miyagi, It conducts regular inspections (general inspections and bogie inspections) of all of the Shinkansen rolling stock owned by JR East, carriage restoration at the time of new carriage delivery, dismantling of retired rolling stock, and various modification work.

In order to provide safe, secure, and comfortable rolling stock for the expanding Shinkansen network, we aim to further improve the quality of service by utilizing our extensive experience in inspections and repairs as well as maintenance data accumulated since we started the business.

Bogie Transfer

Shinkansen carriages entering the center are separated into carriage bodies and bogies, undergo detailed inspection, and then recombined.

Carriage Body Painting

Making expert use of superior painting technologies and high-precision painting facilities, we make the carriage exterior paint shine like new.

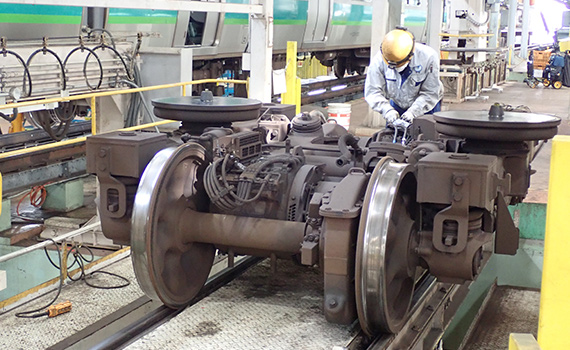

Bogie Disassembly and Inspection

The bogie separated from the carriage body is disassembled into individual parts, each of which is then maintained.

Under-Floor Equipment Removal and Installation

Various parts are removed from the carriage body, transported to the maintenance site for inspection, and then reattached to the carriage body.

Removal and Installation of Contact Coupler

The coupler is removed from the carriage body, transported to the maintenance site for inspection, and then reattached to the carriage body.

Gran Class Seat Maintenance

We maintain the seats that passengers directly touch so that they can be used comfortably.

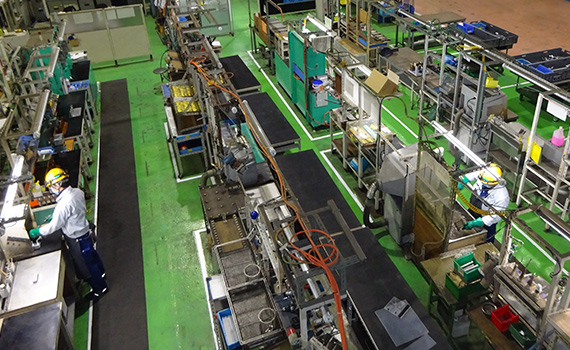

Equipment and Parts Maintenance

Equipment and parts removed from the carriage body or bogie are dismantled, repaired, reassembled, and tested on a dedicated line (site).

Solenoid Valve Maintenance

Solenoid valves removed from the carriage body are inspected and checked for any abnormalities.

Carriage Body Restoration

Newly manufactured Shinkansen carriages are transported with their carriage bodies and bogies separated, and then combined at the center (carriage restoration). Shinkansen carriages are restored jointly by the manufacturer and our company.

Regular Inspection and Repair of JR Conventional Line Rolling Stock

We provide regular inspection and repair services for railway rolling stock based on our extensive track record and experience in order to deliver safe and comfortable transportation services to our railway customers at all times.

Examples of Business Activities (Tokyo Branch)

The Tokyo Branch, located in the JR East Tokyo General Rolling Stock Center in Shinagawa-ku, Tokyo, conducts maintenance on JR East’s rolling stock that mainly runs in the Tokyo metropolitan area, including the Yamanote, Keihin-Tohoku, and Chuo lines,etc.

To ensure that passengers can use our railways with peace of mind, we conduct maintenance according to strict inspection standards.

Removal and Installation of Roof-Top Equipment

We remove pieces of roof-top equipment, such as air conditioning units and pantographs, send them to the maintenance site, and reinstall them after the completion of maintenance.

Inspection and Cleaning of Under-Floor Equipment

We inspect and clean various equipment installed under the floor of the rolling stock, and replace parts on a regular basis.

Door Operating Equipment Maintenance

By adjusting the door operating equipment used to open and close the doors when passengers board and alight the train, and by checking their operation, we confirm that the doors are operating correctly.

Bogie Replacement

We separate the carriage body and the bogie to inspect for damage to the lower part of the carriage body. We also send the separated bogie to the maintenance site, and reinstall the bogie after the completion of maintenance.

Air Conditioner Maintenance

By installing and removing the air conditioners fitted to rolling stock, cleaning heat exchangers, renewing refrigeration cycles, and checking their operation, we ensure the temperature inside the train is consistently comfortable.

Various Machinery Maintenance

We confirm the normal operation of machinery through means such as replacing various parts that make up the equipment.

Carriage Body Transportation

Overhead cranes are used to separate the carriage body and the bogie, and to perform the edge work. The separated carriage body is carried on a powered rolling stock carrier (non-tra) to the carriage body repair site.

Moving Rolling Stock

For rolling stock maintenance, a train must be separated into individual carriages upon entering the factory. After the maintenance, the carriages must be connected into a single train. We use powered switching carriers to move the carriages to be separated and connected.

Public and Private Rolling Stock Maintenance

Utilizing the technologies and skills we have accumulated through our rolling stock maintenance work for JR East, we are entrusted with inspection, repair, and modification work for many public railways and third-sector railways, and we are expanding our business to include other public and private railways.

Moriya Rolling Stock Center

The Moriya Rolling Stock Center conducts inspections and repairs of the brake control equipment and door opening/closing mechanisms of rolling stock for the Metropolitan Intercity Railway Tsukuba Express.

Shimura Rolling Stock Center

The Shimura Rolling Stock Center conducts critical parts inspections and general inspections of the 6300 series for the Tokyo Metropolitan Transportation Bureau Mita Line.

Tokyo Monorail Center

The Tokyo Monorail Center conducts monthly inspections, tire replacement, critical parts inspections, and some maintenance as part of general inspections of rolling stock for the Tokyo Monorail Co., Ltd.

Kawawa Rolling Stock Center

The Kawawa Rolling Stock Center conducts train inspections, monthly inspections, critical parts inspections, and general inspections of the 10000 series for the Yokohama City Transportation Bureau Green Line.

Yashio Rolling Stock Center

The Yashio Rolling Stock Center conducts train inspections, functional maintenance, designated maintenance, and other inspection and repair work as well as replacement of rolling stock for the Tokyo Waterfront Area Rapid Transit Rinkai Line.

Maruyama Branch

The Maruyama Branch conducts general maintenance, including monthly inspections, tire replacement, critical part inspections, and general inspections of rolling stock for the Saitama New Urban Transit New Shuttle.

Sendai Metro Branch

The Sendai Metro Branch conducts critical part inspections and general inspections of rolling stock for the Sendai City Transportation Bureau Namboku and Tozai Lines.

Rolling Stock Technology Development Products

Based on our extensive experience in all aspects of railway rolling stock maintenance, we support railway companies in Japan and overseas with a variety of support services using cutting-edge technologies.

Development of Automatic Tool and Material Transporters

Automatic transportation of parts and tools improves the efficiency of rolling stock inspection and repair operations.

Customization of Conductor

Training Facilities

We add new functions to the training equipment for simulating conductor operations in educational facilities.

Overseas Business

We engage in the business of railway rolling stock maintenance in various regions overseas and provide technical cooperation.

Sales of Rolling Stock Parts

In order to maintain the safe and stable transportation of Japanese-made rolling stock transferred to Indonesia, we sell the parts necessary for maintenance to overseas customers.

We are consistently engaged in planning, proposal, contracting, procurement, packaging, transportation by sea container, and delivery inspection support of necessary parts in accordance with local rolling stock maintenance plans.

Local After-Sales Service

As an after-sales service for delivered parts, we also provide on-site maintenance training. These efforts help improve the safety and quality of rail transportation in Indonesia.